Voith provides intelligent drive components that enable operating in innovative, automated network systems. Voith solutions are operating dependably even under harsh environmental conditions for increased productivity in the mining process. Voith facilitates the safe processing of raw material with maximum efficiency and at the lowest possible cost, characterized by minimal maintenance and low wear and tear.

Voith TVVS Fluid Coupling

Fluid coupling are able to transmit huge amounts of power to machines or conveyors smoothly and efficiently

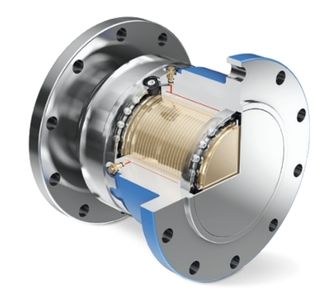

A coupling consists of two primary circumferential components – the pump and the turbine wheel. The pump wheel is connected to the motor and acts like a rotary pump, while the turbine wheel is connected to the drive machine.

Operating fluid flows from the pump wheel directly into the turbine wheel and back to the pump wheel, with power transmission proportional to the fill level in the working circuit. Thanks to a separation of the drive and driven sides, hydrodynamic couplings are able to transfer power without friction or wear, while dampening torsional vibration and torque shocks in the drive chain at the same time. This results in smooth, wear-free power transmission and long operating lifetimes.

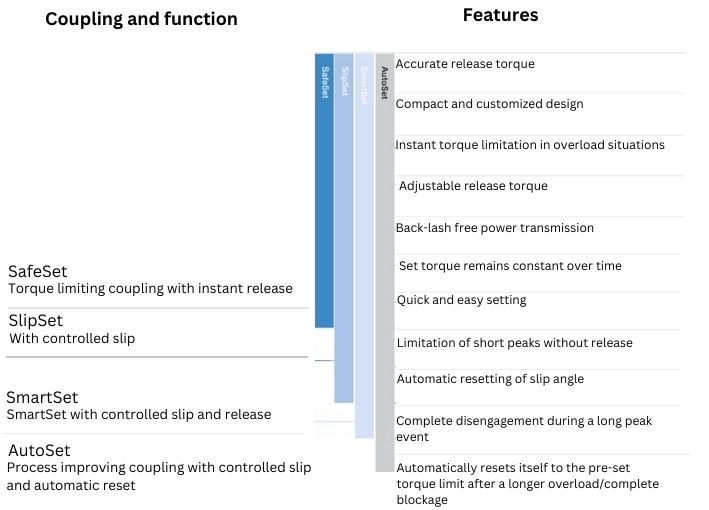

Torque Limiting Couplings

Voith torque limiting couplings are used in many applications in industries worldwide. SafeSet, SlipSet, SmartSet and AutoSet ensure safe operation of the driveline, by releasing or slipping at a very precise torque level. This protects driveline equipment and smoothens production.

Voith torque limiting couplings are customized and can be manufactured in a various ranges and friction diameter

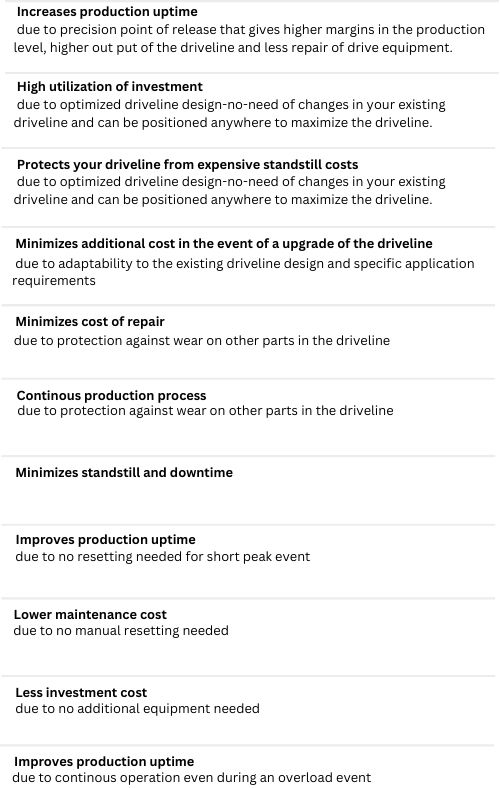

BENEFITS

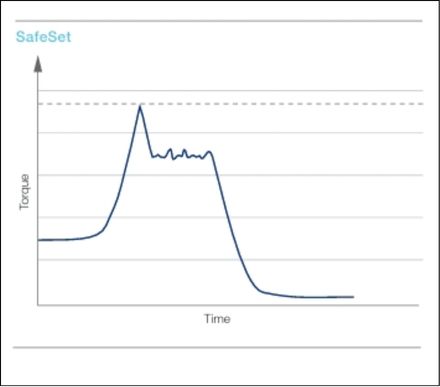

SafeSet with instant release

Operation

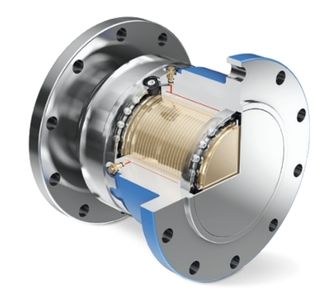

The SafeSet principle is simple: friction and adaptability. No material fatigue or wear ensures constant torque protection during operation. The SafeSet coupling includes a twin-walled hollow sleeve. Friction is generated upon expansion by pressurized hydraulic oil. The integrated shear tube holds pressure to ensure a constant but easy adaptable torque transmission. In an overload situation the SafeSet slips and the shear tube shears off. Oil pressure drops and the frictional surfaces separate. Then the SafeSet rotates on the bearings without transmitting any torque.

Torque capacity available between 1 kNm and 20 000kNm

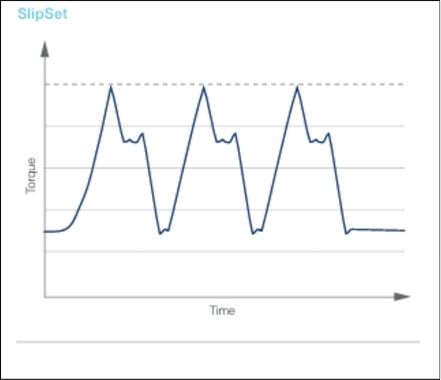

SlipSet with controlled slip

The SlipSet torque limiting coupling ensures continuous production and is designed to instantly slip instead of release in the event of an overload situation. By acting as a shock absorber in drives with frequent torque peaks, the SlipSet prevents time-consuming shutdowns for repair work. The SlipSet torque limiting coupling is perfectly suitable in applications where there is a need of handling short peak loads (smaller than 120deg). The SlipSet units are very compact and can be installed in areas with a minimum of space, to ensure the most optimal position in a drive line.

Operation

In the event of an torque overload, the Slipset will instantly slip and limit the torque to the pre-set level, protecting the driveline. If the blockage is temporary, for example due to inertia effects, the SlipSet slips until the torque peak has passed and the driveline doesn’t have to be stopped.

If the over load persists, the monitoring system name Dtect detects the slippage and informs the operator that the drive train power needs to be adjusted.

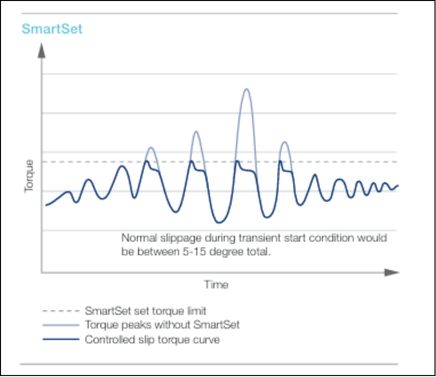

SmartSet with controlled slip and release

Operation

SmartSet is based on the same technology as the SafeSet coupling, but it equipped with SmartSet device that will give the coupling an additional slip feature. This centrifugal device is activated by the rotational speed of the intended application. This enables the coupling to slip without release during high transient torques, there are an inherent part of many applications with synchronous motors.

If the torque peak is of long duration in an overload situation, the SmartSet coupling can fully release as a normal SafeSet coupling and subsequently save the drive train from catastrophic failure.

Torque capacity available from 1 kNm to 15000 kNm.

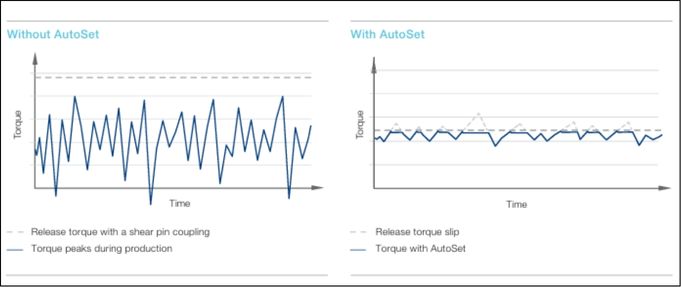

AutoSet with controlled slip and automatic reset

The AutoSet is a torque limiting coupling with a slip function and automatic reset to enhance performance. The primary function of the AutoSet is to distribute torque smoothly by small controlled slippage. As a secondary function the AutoSet will release entirely at torque peaks of long duration and protect drive line equipment from catastrophic failure. This mode will occure successively at slip andles between 30-180 degrees. It is completely automatic and the self-reset function maximizes production uptime.

The AutoSet friction grip is created by a hydraulically adjustable tampered sleeve that denerates the pre-set torque level. Is the set torque is exceeded, the coupling slips and limits the torque with and accuracy of -+ 10% during standard performance. After release the coupling automatically resets itself to the full pre-set torque level and no manual handling is needed. This avoids lengthy stoppage in production.

Torque capacity available between 0.14 to 275 kNm.