NMS products cover crusher, grinding mill, screen, feeder, classifier and others. Core products include GC gyratory crusher, JC Jaw Crusher, CC hydraulic cone crusher, MC hydraulic cone crusher, HS impact crusher, VS vertical-shaft impact crusher, YKR/ZKR vibrating screen, HPF grizzly feeder, MP/MT mobile crushing & screening plant, and CLTC dry-wet dust removal devices.

CRUSHING EQUIPMENT

The crushing equipment such as gyratory crusher, JC jaw crusher, CC single-cylinder hydraulic cone crusher produced by Nanchang Mineral Systems are widely used in various ore and aggregates crushing operations to provide better solutions for mines and engineering

GC Gyratory Crusher

The GC series gyratory crusher is an advance crusher at present, suitable for the primary crushing of various rocks and ores, features as follows: large capacity, high crushing efficiency, large reduction ratio, consistent product size, lower consumption, etc. fit for the application of larger capacity.

JC Jaw Crusher

JC Jaw Crusher is successfully developed by NMS through advanced technology. It is widely used in various hard and abrasive rock. It is possible foundation bolts are not required due to the good balance of the crusher.

CC Cone Crusher

CC Cone Crusher is successfully developed by NMS through introduction of foreign advanced technology and research findings. It is widely used in various hard and abrasive rock conditions.

MC Multi Cylinder

MC series multi-cylinder cone crusher is a new type of high performance cone crusher designed by Nanchang Mineral Systems. It is widely used in metal mine metallurgy industry, construction industry, cement industry, sand and aggregates industry, etc.

Performance characteristics higher crushing ratio, greater procesing capacity, and better product size.

HS Impact Crusher

HS Impact Crusher series is the up-to-date generation. product. 40 years manufacturing experience, hundreds of practical application and the usage of most advanced impact crusher technology make the impact crusher featuring international advanced level quality.

HS Impact Crusher series is widely used in primary, secondary or tertiary crushing of medium hard and low abrasive rock. The chrome alloy hammers and liners could be used for crushing of hard and abrasive rocks.

VS Impact Crusher

VS series impact crusher features in material overflow chamber, choke feeding, deep chamber, catering feeding multiple internal air flow cycling, heavy reliable bearing, oil lubrication, resulting in reliable operation, less maintenance, less operation cost.

VS series impact crusher is widely used for aggregates shaping and sand manufacturing. VS crusher is also the ideal replacement of traditional compressive crusher in metal mining for fines production, or it could be also used for pre-grinding in cement production, which can reduce the energy consumption. in addition, it can be used for glass crushing in recycling business.

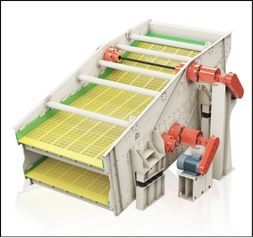

SCREENING EQUIPMENT

Nanchang Mineral Systems feed screening series products adopt advanced design concepts, absorb West German KHD company technology and combine with China’s actual situation to produce advanced level of feed and vibration products, enjoy a high reputation in the industry, and its responsible for formulating JB/T6388-2004 circular vibrating screen standard), JB/T6389-2007 (linear vibrating screen standard), JB/T10729-2007 (large circular vibrating screen standard), JB/T12811-2016 (hydraulic high frequency screen), etc. Nearly ten national industry standards. The product range covers YKRZKR vibrating screen, MOS series elliptical screen, BSMLS series banana screen, HFS/V series high frequency sreen, FX series air screen, and HPF/GPF feeder, etc.

HFS/V Series Hydraulic High Frequency Screen

HFS/V hydraulic high frequency screen based upon NMS’s many years of experience in dry screening and the current advanced technology, is suitable for dry screening of sand making or other fine material.

- Driven by 0-4200 rpm foreign hydraulic vibration motor, the frequency of HFS/V screen is controlled by adjustment of hydraulic flow volume;

- With the latest screening technology, the coarse material can bounce up to very high position, the material close to the screen mesh has more opportunity to be screened;

- High frequency screening is due to the design of vibration beam bearing the screen mesh, so that more vibration force can be obtained with simple and reliable structure of vibration beams;

- With patented mesh tensioned technology, it is easier to replace the screen mesh due to the simple design structure;

NFS Flip-Flow Screen

NFS series flip-flow screen has completely changed the non-motion characteristics of screen surface of traditional vibration screen. When the vibration intensity of the screen box is 3-4g, the vibration intensity offlip-flow screen surface reaches 30-50g. It has good screening effect for sticky and wet materials that are difficult to screen.

- the screen surface has extremely high vibration intensity, which is conducive to the scattering and screening of materials and solves the problem of material agglomeration;

- the screen is made of polyurethane, which has a very high opening rate and service life;

- when the screen is tensioned and relaxed the hole will be deformed to a certain extent, so that the materials bonded to the screen are easy to fall off, so as to realize the self-cleaning and avoid the binding and blocking of materials to the screen

- low energy consumption, small impact on foundation, small amplitude of equipment and high reliability.

the main vibration frame is circular; and the floating frame is elliptical with the long axis parallel to the screen surface, which has a large processing capacity, is more conducive to the screening of materials, and the track of floating frame is stable with high reliability.

MLS-B Series Banana Screen

MLS-B series banana screens are recommended for applications of high load, heavy tough applications in metal mine, coal etc. According to the principle of uniform-thickness screening proposed by Boorse Seine, with 5 to 6 sloped sections. And the unique design extraordinary fits the screening of materials in which there is a high content of medium or fine particles, such as coal. The large banana type screens is favored by users with its high handling capacity high efficiency and reliable performance, and used in coal grading dewatering desiccation and deslime, as the ideal replacement to the existing circular or linear motion screens in coal plants.

- VB box type exciter with great force and high acceleration standard SKF Or FAG bearings;

- High sealing performance by labyrinth and mechanical dust seal;

- the unique design of the hopper to increase screen area;

- With low noise, high performance and minimal maintenance;

- The amplitude can be adjusted by changing the weight block.

YKH-H/SK Series Circular Screen

YKR?ZKR vibration screen is designed and developed with the world latest technology. The screening machine has been improved upon decades of experience in mining and aggregate applications.

It is suitable for various screening conditions of stone, metalurgy, metal mining, coal etc. YKH-H with feeding size less than 300mm and separation size between 2-150mm, YKR- SK with feeding size less than 250mm and separation size between 2-76mm;

ZKR Series Linear Screen

ZKR heavy linear screens are recommended for applications of high load, heavy tough operations in metallurgy, metal mine, coal and aggregates for separation, dewatering and refining with feed top-size 50mm.

Screening media matched includes stainless steel mesh and polyurethane panel.

MLS-B Series Banana Screen

MLS-B series banana screens are recommended for applications of high load, heavy tough applications in metal mine, coal etc. According to the principle of uniform-thickness screening proposed by Boorse Seine, with 5 to 6 sloped sections. And the unique design extraordinary fits the screening of materials in which there is a high content of medium or fine particles, such as coal. The large banana type screens is favored by users with its high handling capacity high efficiency and reliable performance, and used in coal grading dewatering desiccation and deslime, as the ideal replacement to the existing circular or linear motion screens in coal plants.

- VB box type exciter with great force and high acceleration standard SKF Or FAG bearings;

- High sealing performance by labyrinth and mechanical dust seal;

- the unique design of the hopper to increase screen area;

- With low noise, high performance and minimal maintenance;

- The amplitude can be adjusted by changing the weight block.

YKH-H/SK Series Circular Screen

YKR?ZKR vibration screen is designed and developed with the world latest technology. The screening machine has been improved upon decades of experience in mining and aggregate applications.

It is suitable for various screening conditions of stone, metalurgy, metal mining, coal etc. YKH-H with feeding size less than 300mm and separation size between 2-150mm, YKR- SK with feeding size less than 250mm and separation size between 2-76mm

NJ Exciter Series Screen

For higher screening performance or easier exciter installation, YKR/ZKR-NJBS or TSK screen can be equipped with NJ exciters.

NJ exciter uses SKF or FAG bearing, so that higher screening performance and longer endurance can be obtained

YKH/ZKR-NJ Series Screen

YKR/ZKR-NJ series heavy screens are recommended for applications of high load, heavy tough applications in metallurgy, metal mine, coal etc.

With feeding size less than 300mm, and separation size ranging from 3 to 150mm, while ZKR-NJ heavy linear motion screen can process the max feeding size less than 50mm with separation size ranging from 0.25-50mm.

NJ Exciter Series Screen

For higher screening performance or easier exciter installation, YKR/ZKR-NJBS or TSK screen can be equipped with NJ exciters.

NJ exciter uses SKF or FAG bearing, so that higher screening performance and longer endurance can be obtained.